Crimped Fin Tube (Spiral Tension...

read moreEXTRUDED FIN TUBE (BIMETALLIC FIN TUBE):-

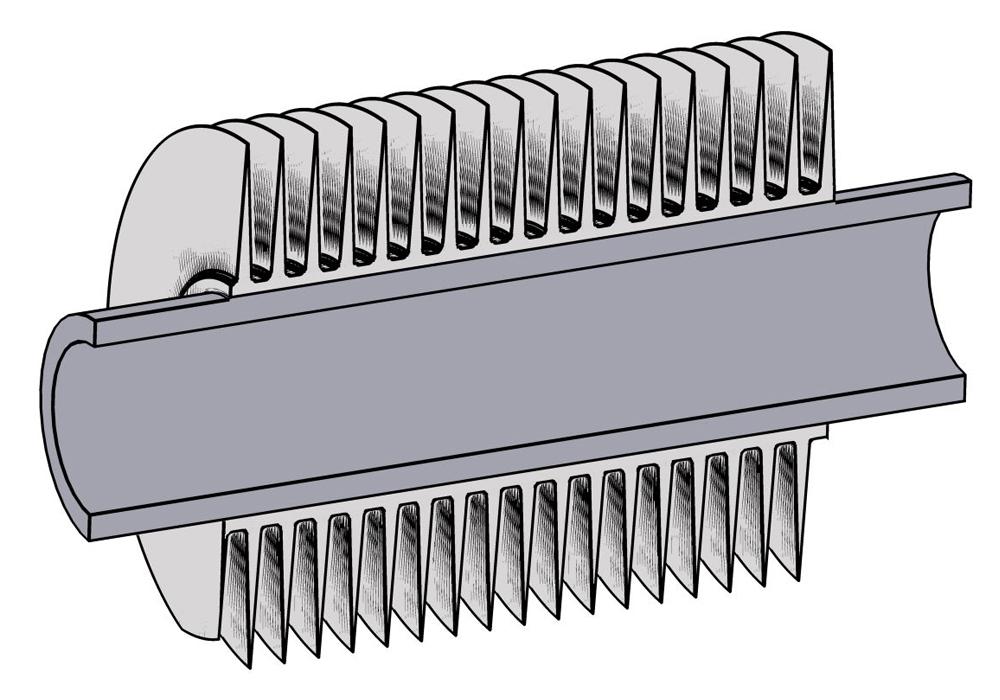

The Extruded Fin Tube also known as Bimetallic Fin Tube is one of the most preferred finning processes for various applications.

The fins are manufactured by Extruding the Fins on the Aluminum Muff Tube which is made to Fit with close tolerance over the Base Tube.

The Extrusion takes place on a Continuous Fin Extruder with Three Tooling rolls and extrusion takes place at high pressures in the range of 1200 psi. Because of the cold working process the Bond between the Tube and fin is flawless and hence gives excellent Heat Transfer Efficiency. At the same time the mechanical strength of the fins is also enhanced drastically.

These Fin Tubes find application in AIR FIN COOLERS, DRIERS, RADIATORS etc and are preferred in Industries like Food and Agriculture, Power Plants, Chemical Industries, Steel Plants, and Chiller Plants etc.

Properties of Extruded Fin Tubes (Bimetallic Fin Tube):-

Fin To Tube Bond:- Excellent

Heat Transfer Efficiency:- Excellent

Mechanical Resistance:- Excellent (Hence can be frequently cleaned with high pressure jets unlike other fin tubes. Thereby reducing down time and increasing overall life)

Corrosion Protection:- Gives excellent corrosion protection to the base tube since it entirely covers the base tube (except bare ends).

Temperature Range:- Upto Maximum 300 Deg C

Manufacturing Range (Extruded Fin Tube/Bimetallic Fin Tube):-

|

Sr. No |

Particulars |

Range |

|

1 |

Base Tube Material |

Stainless Steel, Carbon Steel, Alloy Steel, Titanium, Copper, Duplex Stainless Steel, and Inconel etc. (all material in the theoretical limit) |

|

2 |

Base Tube Outside Diameter |

12.70 mm to 38.10 mm |

|

3 |

Base Tube Thickness |

1.50 mm And Above |

|

4 |

Base Tube Length |

500 mm Min To 15000 mm |

|

5 |

Fin Material |

Aluminum, Copper |

|

6 |

Fin Thickness |

0.3mm, 0.35mm, 0.4mm, 0.45mm, 0.55mm, 0.60mm, 0.65mm |

|

7 |

Fin Density |

197 FPM (5 FPI) to 433 FPM (11 FPI) |

|

8 |

Fin Height |

9.8 mm to 16.00 mm |

|

9 |

Bare Ends |

As per Client Requirement |

|

10 |

Manufacturing Capacity |

5,00,000 Meter Per Annum |

We can supply material on urgent delivery basis because of large stock and relations with raw material suppliers. We use only Prime Quality base tube and Aluminum Material.

The Extruded fin Tubes can be supplied with EN 10204 EN 3.1 and EN 3.2 certifications. We can provide Third Party Inspection from any reputed inspection agency.

EXTRUDED FIN TUBE CROSS SECTION

EXTRUDED FIN TUBE ACTUAL TUBES SUPPLIED TO THE CUSTOMER

1) What is Fin Tubes?

Fin Tubes or Finned Tubes are a type of heat exchanger tubes. They are used mainly in an air-cooled type heat exchanger where the exchange of heat takes place between gas flowing on the Fins and the fluid flowing inside the Fin Tubes. The main purpose is to increase the surface area to facilitate more exchange of heat between the medium and the air.

2) What is Extruded Fin Tubes or Bi-Metallic Fin Tubes?

Extruded Fin Tubes or Bi-Metallic Fin Tubes are a type of fin tubes that have extruded fins from the outer surface. The base tube is made to slide inside an outer tube made of copper or aluminum. Then, this assembly of the inner and outer tube is passed through an automatic extrusion machine. During the extrusion process, the fin is extruded from the outer tube to the desired height, thickness, and density configuration.

3) What is an extruded fin tube made of?

Extruded Fin Tubes or Bi-Metallic Fin Tubes are made of two main components:

We can supply the Extruded Fin Tubes or Bi-Metallic Fin Tubes in both the combinations. Since this type of fin tube generally incorporates two different types of MOC for base tubes and fin material these are widely known as Bi-Metallic Fin Tubes also.

4) Where are Extruded Fin Tubes used?

Extruded Fin Tubes are mainly used in air fin coolers and different types of air-cooled radiators. They mainly find application in areas where the heat exchanger or the air fin cooler is exposed to a lot of harsh environment. They are preferred in the corrosive atmosphere mainly because of the following benefits:-

The main industries in which the Extruded Fin Tubes or Bi-Metallic Fin Tubes find service are Process Chemical Plants, Refineries, Gas Processing Plants, Steel plants, Rice Processing Plants, Power Plants, Fertilizer Manufacturing Plants, etc.

5) Why should you buy Extruded Fin Tubes manufactured by Anand Seamless Ltd?

Anand Seamless Tubes is the only Tube or Fin Tube manufacturer in India that produces the Base Tubes and Fin Tubes under the same roof. This gives a very strategic and commercial advantage to our clients as we have a big stock of base tubes readily available. Buying extruded fin tubes from us also has other benefits, including fewer hassles and costs to manage suppliers for Base Tubes and Fin Tubes, capital blocking for a shorter period, saved transportation costs, reduced TPI costs, etc.